The Wonders of Borosilicate Tubing: Unveiling Its Versatility

Introduction:

Borosilicate tubing, a glass material with exceptional properties, holds a pivotal role in numerous industrial, scientific, and artistic applications. In this comprehensive article, we will explore the remarkable world of borosilicate tubing, uncovering its composition, extraordinary attributes, manufacturing methods, and its extensive spectrum of uses.

Section 1: Understanding Borosilicate Tubing

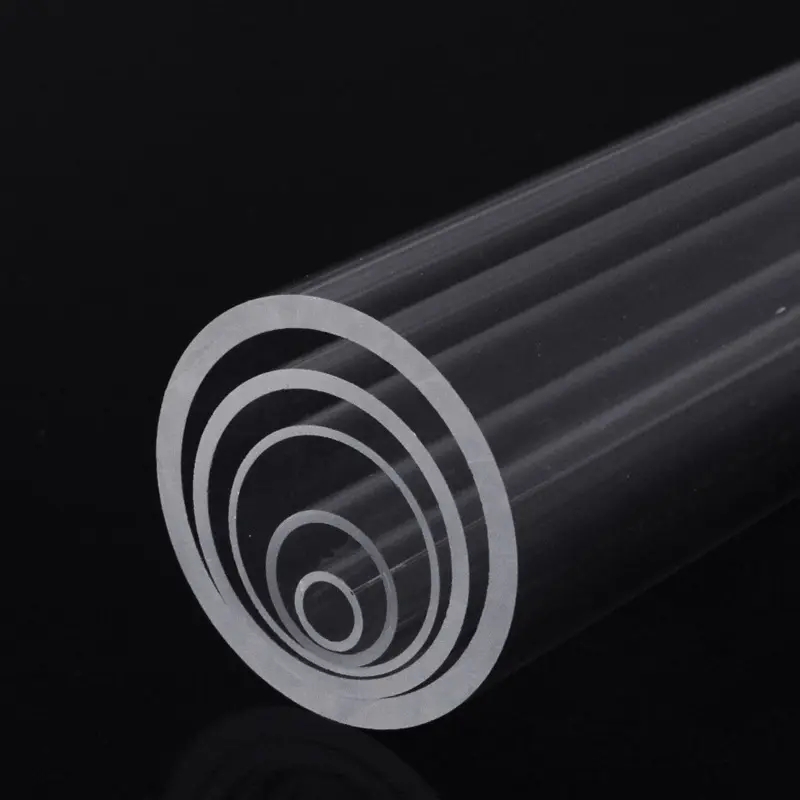

Borosilicate tubing is a glass variant that incorporates a substantial boron oxide content in its composition. This unique blend of boron and silica imparts borosilicate glass with distinct qualities, including high thermal resistance, unparalleled chemical durability, and remarkable transparency. Its low coefficient of thermal expansion (CTE) further enhances its suitability for scenarios involving abrupt temperature fluctuations.

Section 2: The Distinctive Properties of Borosilicate Tubing

High Thermal Resistance: Borosilicate tubing is engineered to withstand extreme temperature variations, rendering it an optimal choice for applications requiring exposure to high temperatures, such as laboratory glassware and industrial furnaces.

Exceptional Chemical Durability: Thanks to its robust chemical resistance, borosilicate glass is the preferred material for storing and transporting sensitive substances like pharmaceuticals and chemicals, ensuring the utmost safety and stability.

Low CTE: The low coefficient of thermal expansion minimizes the risk of cracking or shattering during rapid temperature fluctuations, ensuring the glass’s longevity and reliability.

Superior Transparency: Renowned for its excellent optical clarity, borosilicate glass is extensively used for high-quality optical components, camera lenses, and artistic glasswork, including stunning glass sculptures.

Section 3: The Manufacturing Process

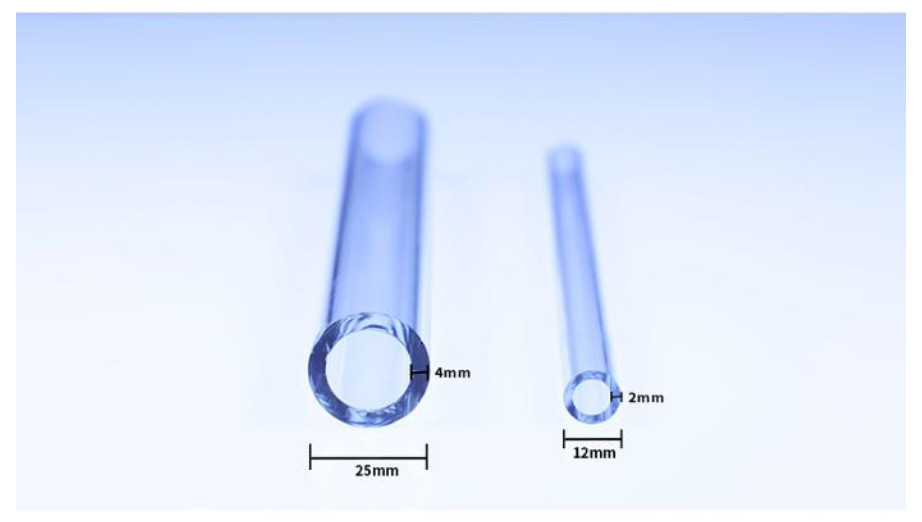

The production of borosilicate tubing entails meticulous melting and blending of high-purity silica and boron oxide. This concoction is then fashioned into tubes through various methods, including the Danner process and the Vello process. Subsequently, the tubing undergoes gradual cooling to mitigate internal stresses, enhancing its structural integrity and resilience. It can then be tailored to meet specific requirements through cutting, polishing, and shaping.

Section 4: Wide-Ranging Applications of Borosilicate Tubing

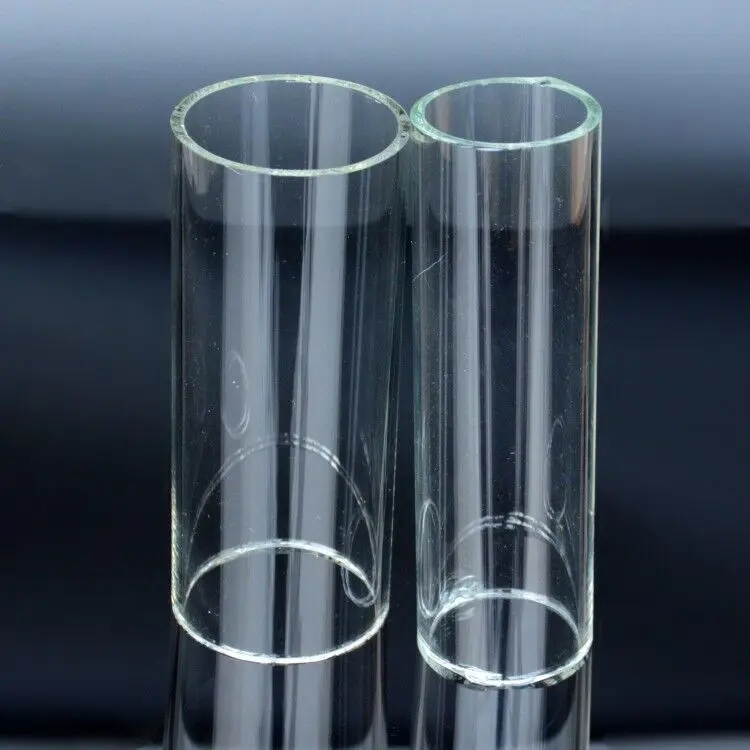

Laboratory Glassware: Borosilicate tubing finds extensive use in the fabrication of laboratory glassware such as beakers, test tubes, and pipettes, owing to its chemical resistance and optical clarity.

Pharmaceutical Packaging: Many pharmaceutical companies rely on borosilicate glass vials and containers for the secure storage of delicate medications and chemicals, ensuring product stability and safety.

Lighting and Optics: The glass’s optical clarity makes it an impeccable choice for high-quality optical lenses, camera lenses, and artistic glass creations like intricate sculptures.

Industrial Applications: Borosilicate tubing is integral to a multitude of industrial processes, including semiconductor manufacturing, chemical processing, and oil refineries, due to its capacity to endure extreme temperatures and harsh chemicals.

Conclusion:

Borosilicate tubing is an extraordinary material with multifaceted applications. Its unparalleled attributes, encompassing high thermal resistance, exceptional chemical durability, and transparency, establish it as an indispensable component across diverse industries. Whether you are a scientist, artist, or industrial engineer, borosilicate tubing is likely to be a fundamental element in your work. A profound comprehension of its composition, properties, and manufacturing processes is pivotal for fully harnessing the immense potential of this versatile material.