Borosilicate Tubing: A Comprehensive Guide

Introduction:

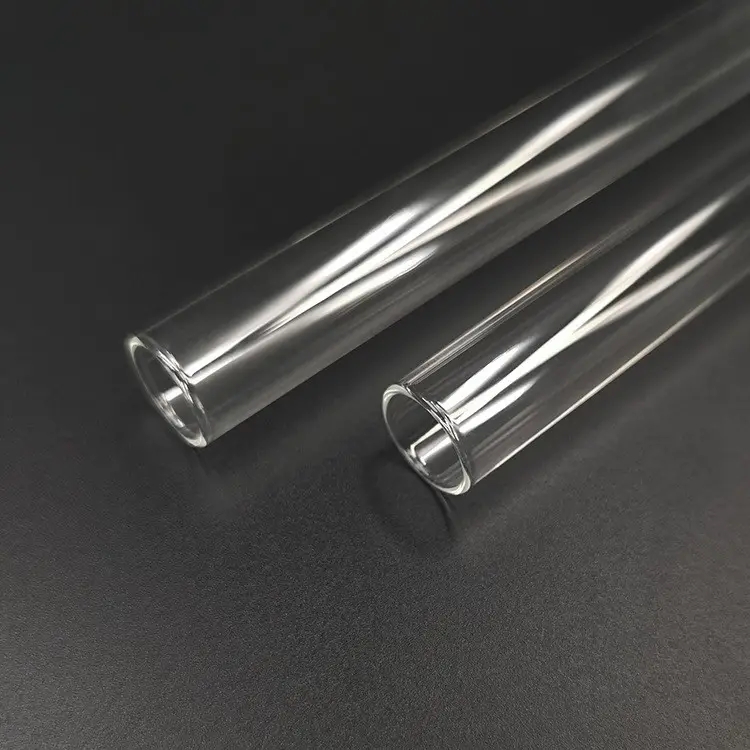

Borosilicate tubing is a versatile and essential material in various industrial and scientific applications. It is known for its exceptional properties, making it a popular choice for laboratory glassware, pharmaceutical packaging, and even artistic glasswork. In this article, we will delve into the world of borosilicate tubing, exploring its composition, properties, manufacturing process, and its wide-ranging uses.

Section 1: What is Borosilicate Tubing?

Borosilicate tubing is a type of glass that contains a significant amount of boron oxide in its composition. This unique blend of boron and silica gives borosilicate glass several advantageous characteristics, including high thermal resistance, exceptional chemical durability, and superior transparency. Its low coefficient of thermal expansion (CTE) also makes it an ideal choice for applications that involve abrupt temperature changes.

Section 2: Properties of Borosilicate Tubing

High Thermal Resistance: Borosilicate tubing can withstand extreme temperatures, making it suitable for use in high-temperature applications like laboratory glassware and industrial furnaces.

Exceptional Chemical Durability: This glass type is highly resistant to chemical corrosion, which makes it an excellent choice for storing and transporting sensitive substances such as pharmaceuticals and chemicals.

Low CTE: The low coefficient of thermal expansion reduces the risk of cracking or shattering when subjected to rapid temperature fluctuations.

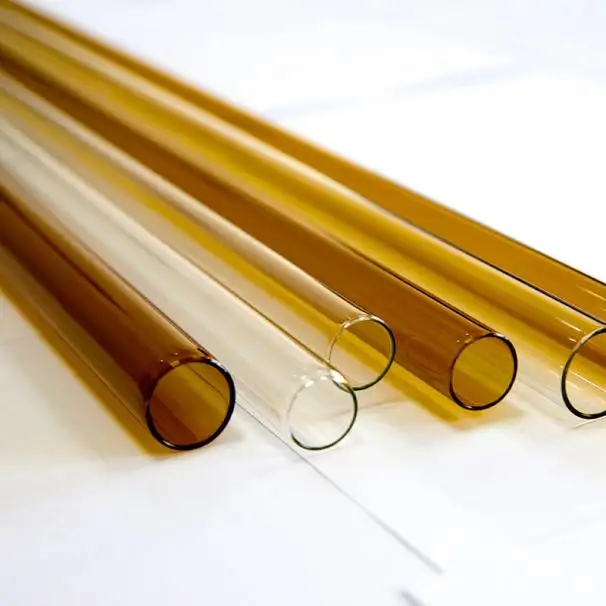

Superior Transparency: Borosilicate glass is renowned for its excellent optical clarity, making it ideal for optical components and artistic glasswork.

Section 3: Manufacturing Process

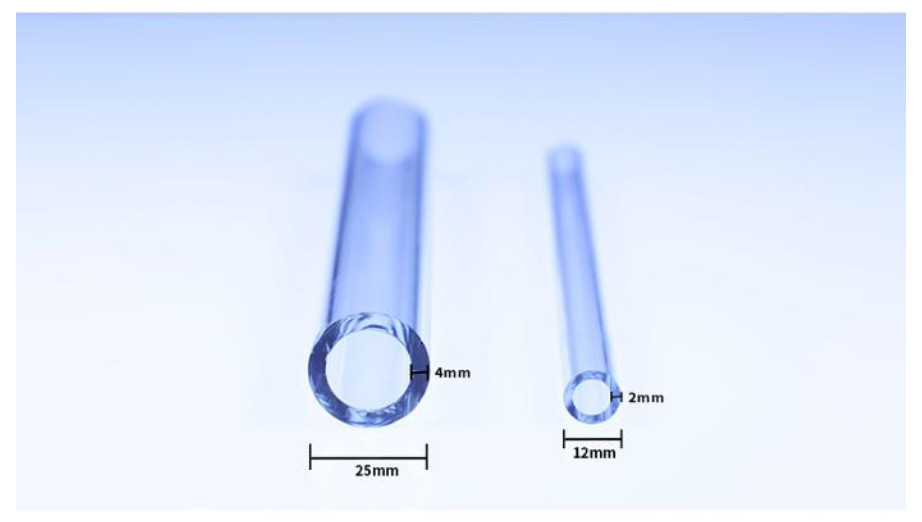

The manufacturing of borosilicate tubing involves carefully melting and blending high-purity silica and boron oxide. The mixture is then formed into tubes through various methods, including the Danner process and the Vello process. After forming, the tubing is slowly cooled to reduce internal stresses, enhancing its strength and durability. Following this, it can be cut, polished, and shaped according to specific requirements.

Section 4: Common Uses of Borosilicate Tubing

Laboratory Glassware: Borosilicate tubing is widely used in the production of laboratory glassware such as beakers, test tubes, and pipettes due to its chemical resistance and clarity.

Pharmaceutical Packaging: Many pharmaceutical companies use borosilicate glass vials and containers to store sensitive medications and chemicals, ensuring their stability and safety.

Lighting and Optics: Its optical clarity makes it an excellent choice for high-quality optical lenses, camera lenses, and artistic glasswork, such as glass sculptures.

Industrial Applications: Borosilicate tubing is employed in numerous industrial processes, including semiconductor manufacturing, chemical processing, and oil refineries, due to its resistance to extreme temperatures and harsh chemicals.

Conclusion:

Borosilicate tubing is a remarkable material with a broad range of applications. Its unique properties, including high thermal resistance, exceptional chemical durability, and transparency, make it an indispensable choice in various industries. Whether you are a scientist, an artist, or an industrial engineer, borosilicate tubing is likely to play a crucial role in your work. Understanding its composition, properties, and manufacturing process is key to harnessing the full potential of this versatile material.